Welcome to GeneratorStop.com! We have all generator related things you need from generator parts, repairs for your broken generator, reviews, tools and more!

Lima Generator Repair & Parts

Power outages in Lima? Don’t sweat it. Here’s your quick guide to trusted repair shops, where to score parts, and what to keep in mind—plus some must-have gear like a portable generator or a protective cover.

Read more >>

Oslo Generator Repair & Parts

Need generator help in Oslo? No worries. Here’s your quick guide to repair shops, parts dealers, and smart buys—like portable generators and weatherproof covers.

Read more >>

San Diego Generator Repair & Parts

Lights out in San Diego? No worries. Here’s your go-to guide for local generator repair shops, reliable parts dealers, and handy maintenance tips—plus smart picks like portable generators and protective covers.

Read more >>

Saint Paul Generator Repair & Parts

Lights out in Saint Paul? Don’t panic. Here’s your go-to guide for fast generator repair, trusted parts shops, and handy must-knows—plus smart online picks like portable generators and generator covers.

Read more >>

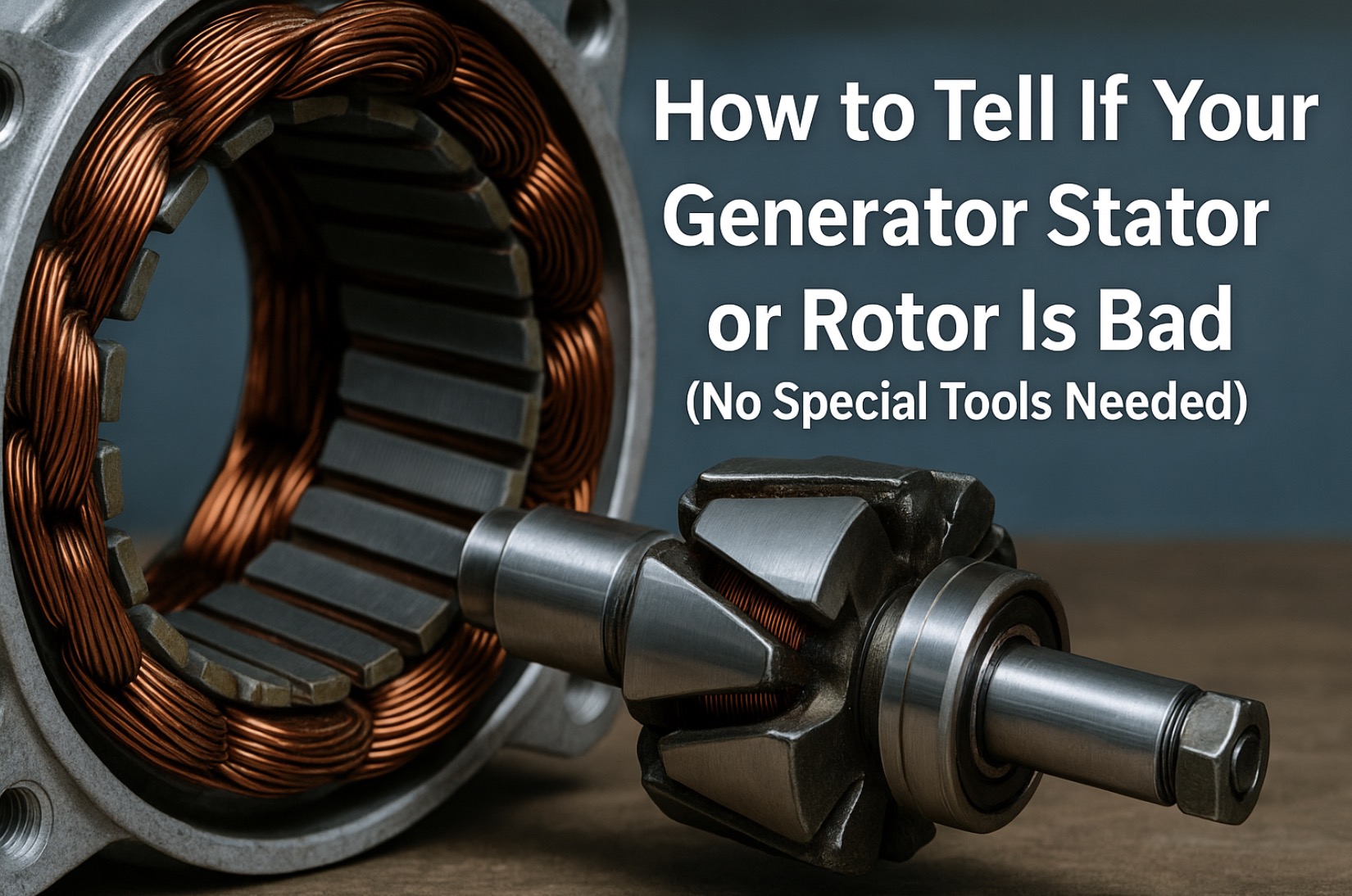

How to Tell If Your Generator Stator or Rotor Is Bad (No Special Tools Needed)

When your generator runs but delivers no power, or the voltage is weak and unstable, it is natural to wonder if the alternator itself is bad. The alternator is made up of two main pieces: the stationary windings (stator) and the rotating field (rotor). The good news is that you can often get a strong clue about which one is at fault using simple checks, basic hand tools, and—optionally—a cheap multimeter.

Read more >>

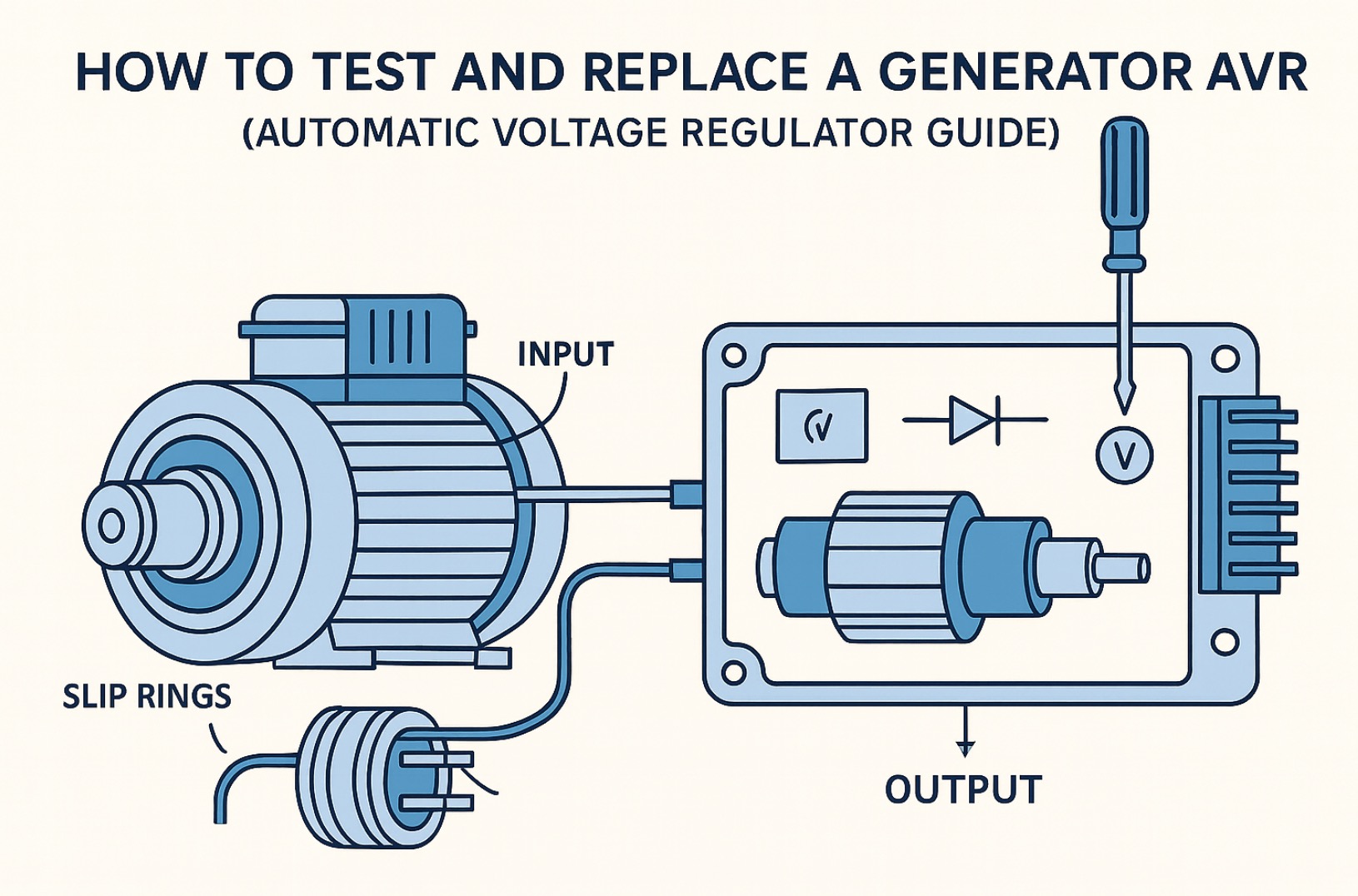

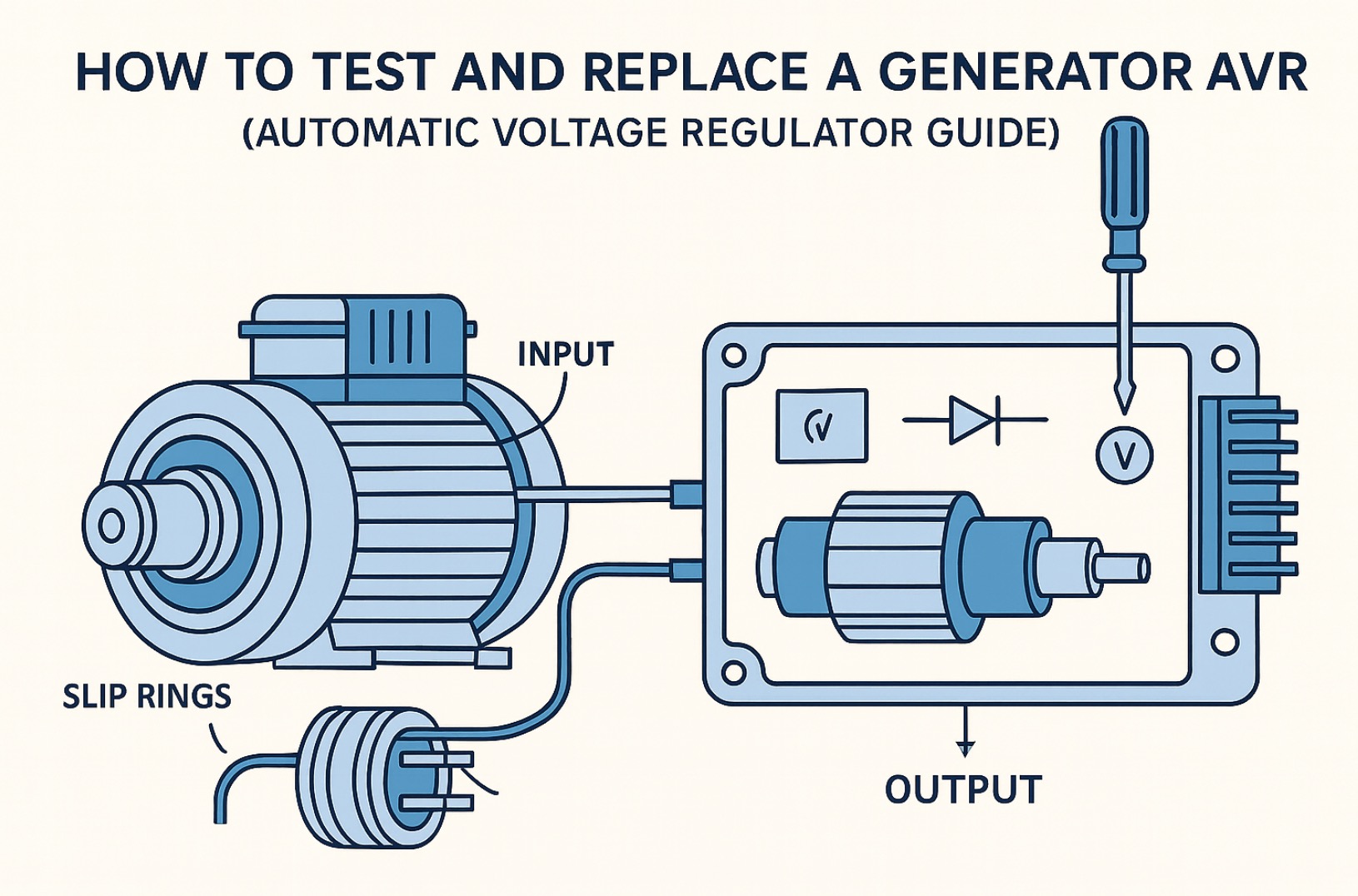

How to Test and Replace a Generator AVR at Home (Automatic Voltage Regulator Guide)

When a generator engine runs fine but the voltage is low, high, or all over the place, the automatic voltage regulator (AVR) is one of the first suspects. The AVR controls the alternator’s output by regulating the excitation going into the rotor. A failed or weak AVR can leave you with dim lights, fried electronics, or no output at all. This guide walks you through how to safely test and replace a typical portable generator AVR at home.

Read more >>

Gas Generator Only Runs on Choke? Carburetor Repair Guide to Fix the Problem

When a gas generator will only stay running with the choke partially or fully on, it usually means the engine is starving for fuel and running too lean. The choke is artificially enriching the mixture just enough to keep it alive. In most cases, that points to a dirty, varnished, or partially blocked carburetor—not a major engine failure. This step-by-step carburetor repair guide walks you through what to check and how to clean or repair the carb before calling a shop. For a broader look at how fuel, spark and electrical parts fit together, you can also explore the overview in Generator Parts and Repairs.

Read more >>

Generator Runs but No Power to the House? 7 Things to Check Before Calling a Technician

Few things are more frustrating than hearing your generator humming away while your house stays dark. The good news: in many cases, the problem is somewhere between the generator outlet and your home’s electrical panel—not deep inside the generator itself. Before you call a technician (and pay diagnostic fees), walk through these common checks to narrow down the cause.

Read more >>